Definition: A substation is a part of electrical energy generation, transmission, and distribution system. Substations transform voltage from high to low, or low to high, or perform any of several other important functions. Between the generating station and consumer, electric power may flow through several substations at different voltage levels. A substation may include transformers to change voltage levels between high transmission voltages and lower distribution voltages, or at the interconnection of two different transmission voltages.

Type of Sub-Station: The majority of the sub-stations in the power system are concerned with the changing of voltage level of electric supply. These are known as Transformer Substation because transformer is the main component employed to change the voltage level. Depending upon the purpose served, Transformer Substation may be classified into:

1. Step-up sub-station

2. Primary grid sub-station

3. Secondary sub-station

4. Distribution sub-station

Pole Mounted Substation:

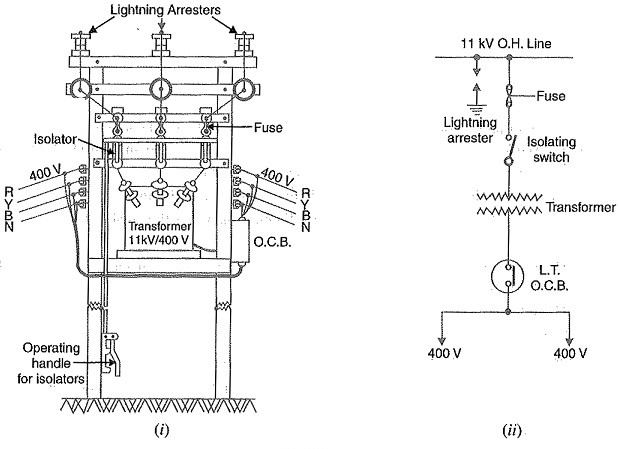

It is a distribution sub-station placed overhead on a pole. It is the cheapest form of sub-station as it does not involve any building work. Fig (i) shows the layout of pole-mounted sub-station whereas Fig (ii) shows the schematic connections. The transformer and other equipment are mounted on H-type pole (or 4-pole structure).

The

11kV line is connected to the transformer (11kV / 400 V) through gang isolator

and fuses. The lightning arresters are installed on the H.T. side to protect

the sub-station from lightning strokes. The transformer steps down the voltage

to 400V, 3-phase, 4-wire supply. The voltage between any two lines is 400V

whereas the voltage between any line and neutral is 230 V. The oil circuit

breaker (O.C.B.) installed on the L.T. side automatically isolates the

transformer from the consumers in the event of any fault. The pole-mounted

sub-stations are generally used for transformer capacity up to 200 kVA. The

following points may be noted about pole-mounted sub-stations:

- There should be periodical check-up of the dielectric strength of oil in the transformer and O.C.B.

- In case of repair of transformer or O.C.B., both gang isolator and O.C.B. should be shut off.

Bus-Bar: It is one of

the most important elements in an electrical power substation. It is a type of

conductor carrying an electrical current to which many connections are made. In

other words, bus-bar is a type of electrical junction in which the incoming and

outgoing of electrical current take place.

When the fault occurs in the bus- bar, then

all the circuit equipment connected to that section must be tripped out to give

complete isolation in the shortest possible time e.g. (60ms) so that the damage

is avoided to the installation due to heating of conductors.Insulator: It is used in generating stations and substations to fix and insulate the bus bars systems. They may be subdivided into post and bushing type. A post insulator consists of porcelain body and their cap is made up of cast iron. It is directly bolted to the busbars by means of bus-bar clamps. A bushing or through insulator consists of porcelain-shell body, upper and lower locating washes used for fixing the position of bus-bar or rod in a shell.

Circuit Breaker: The circuit breaker is a type of electrical switches which is used for opening or closing of electrical circuit whenever faults occur in the system. It consists of two moving contacts which are normally closed. Whenever the fault occurs in the system, the relay sends the tripping command to the circuit breaker and hence their contacts are moved apart. Thus, the fault occurs in the system becomes clear.

Power Transformer: Power transformers are used for

stepping up the voltage for transmission at generating station and for stepping

down the voltage for further distribution at main step-down transformer

substations. Usually naturally cooled, oil immersed type two winding, three

phase transformers, are used for rating up to 10 MVA. The transformer for

rating more than 10 MVA, are usually air blast cooled. For very high rating,

the force oil, water cooling and air blast cooling may be used. Such type of

transformer operated at full load, and it is disconnected at light load hours.

The power transformers are arranged in banks and can be thrown in parallel with

other units. Thus, the efficiency of the power transformer is maximum at full

load (i.e., with iron loss to full load copper loss ratio 1:1).

Instrument

Transformer: Instrument transformer

is used to reduced high voltages and currents to a safe and practical value

which can be measured by conventional instruments (normally range is 1A or 5A

for current and 110 V for voltage). It is also used for actuating the AC type

protective relay by supplying the current and voltage by the current and

potential transformer. Instrument transformers are classified into two types

(ii) Potential Transformer: A voltage transformer may be defined as an potential transformer for the transformation of voltage from a higher value to the lower value.

Apart from these above equipment, there are some others essential equipment in a sub-station. I will come back soon with them.

Thanks for reading.

2 Comments

thanks vai

ReplyDeleteYou are most welcome

ReplyDelete